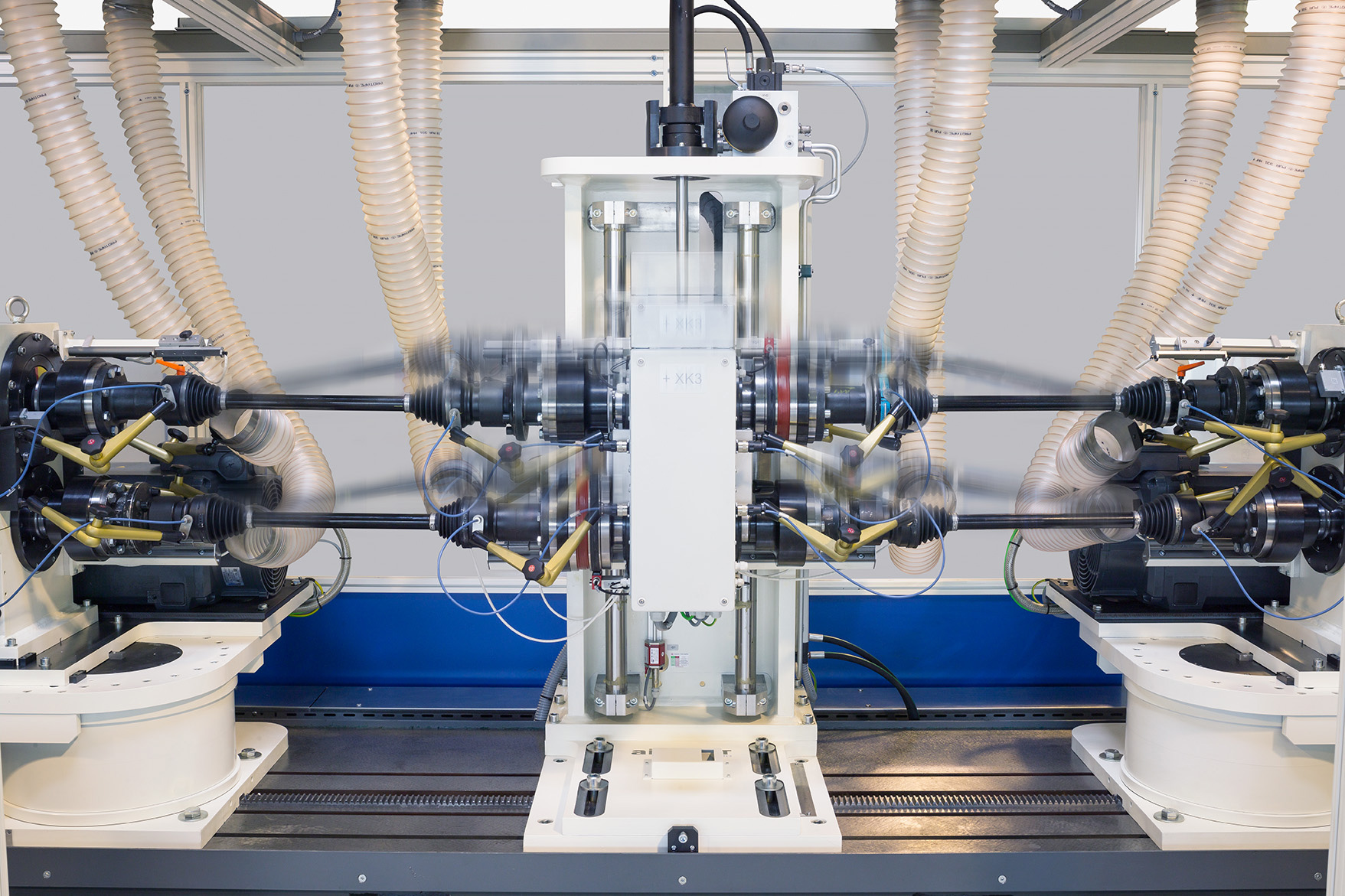

End-of-Line test rig for safety clamps

The end-of-line test rig is part of the production line and is fully integrated in the process. It must be able to keep pace with the production machine cycles. It is also subject to the same demanding requirements in terms of availability, ease of maintenance and spare part availability. The test rig features integrated OK/NOK detection. It also offers tamper-proof storage of KPIs and test protocols, and can be integrated into the customer’s ERP system.

-

Torque Max. 15,000 Nm Speed 10 rpm Angle resolution < 2arcsec Compressed air pressure

0-6 bar Test specimen identification Via 2D matrix code Test specimen programme Automatic selection Specimen-specific installation instructions OK/NOK identification Automatic test protocol Torque

Max. 15,000 Nm

Speed

10 rpm

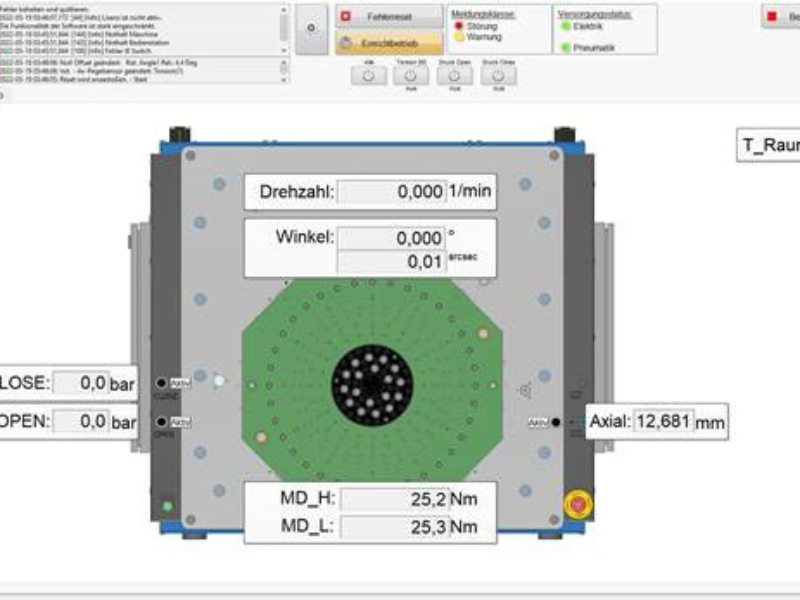

Angle resolution

< 2arcsec

Compressed air pressure

0-6 bar

Test specimen identification

Via 2D matrix code

Test specimen programme

Automatic selection

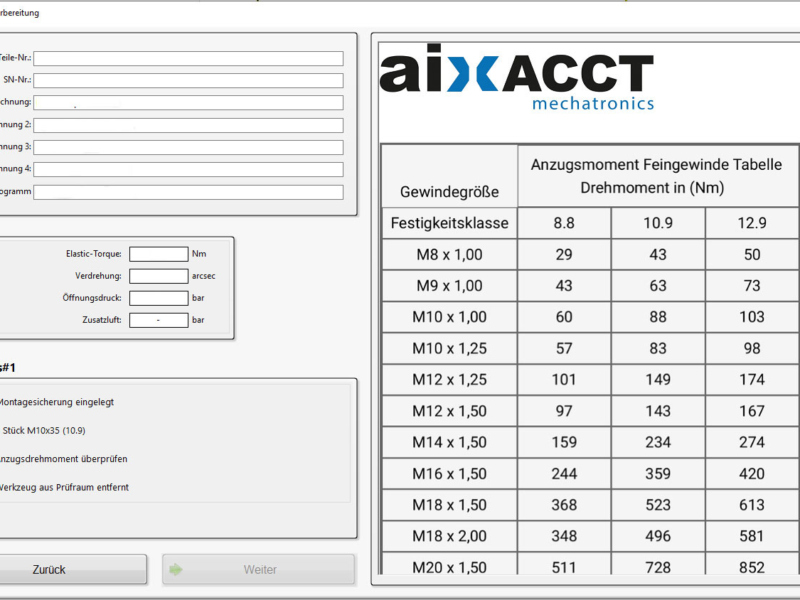

Specimen-specific installation instructions

OK/NOK identification

Automatic test protocol

Additional features:

- Grease detection

- Axial force measurement

- Backlash measurement

- Road data simulation

- Efficiency measurement

The technical data is standard data and can be altered upon request.