Torsion test rigs allow the testing of components under torque (Nm). This kind of testing uses a variety of drive systems and actuators according to requirements, depending on whether a component should be subjected to static or dynamic stress.

-

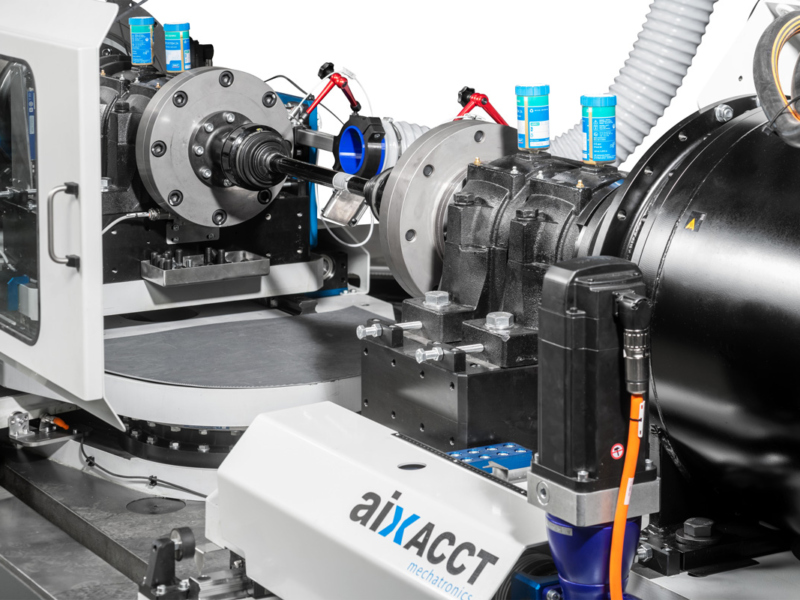

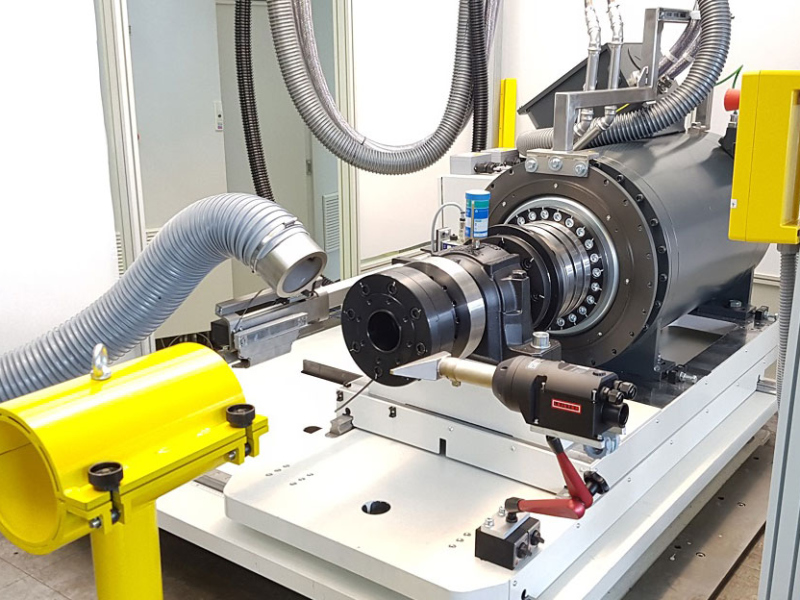

MMFTR – Multi-modular function test rig

Multi-modular function test rigs (MMFTR) enable torsion tests on components under variable test conditions. These include test procedures such as impact testing, snap start, double fatigue, rotational fatigue, differential testing and clutch testing.

MMFTR

Torque ± 8,000 Nm

> ramp 150 Nm / 200 msSpeed ± 600 rpm / ± 700 rpm Lenkwinkel 0 - 60° Radial displacement 0 - 400 mm Airflow simulation 0-30 m/s Joint temperature control RT-200°C Test specimen length 300 - 1,500 mm (CL-CL) or according to customer wishes Torque

± 8,000 Nm

> ramp 150 Nm / 200 ms

Speed

± 600 rpm / ± 700 rpm

Lenkwinkel

0 - 60°

Radial displacement

0 - 400 mm

Airflow simulation

0-30 m/s

Joint temperature control

RT-200°C

Test specimen length

300 - 1,500 mm (CL-CL) or according to customer wishes

The technical data is standard data and can be altered upon request. -

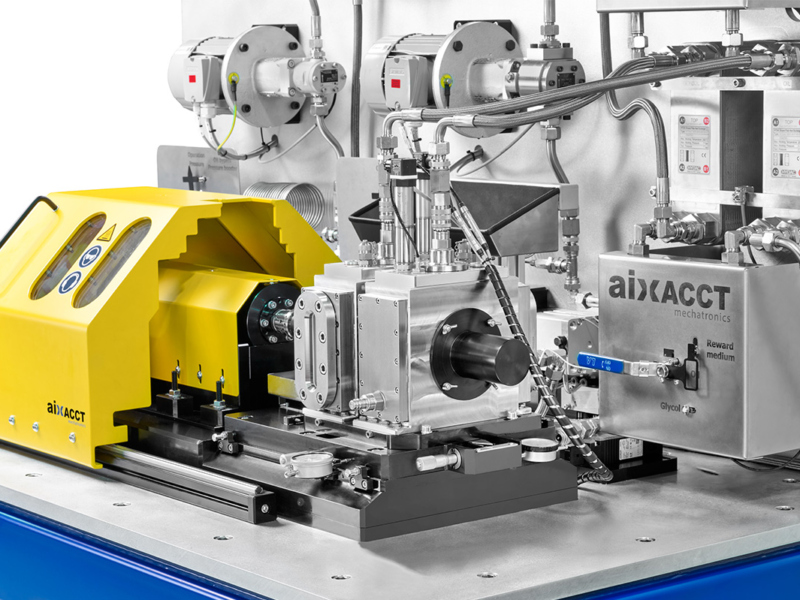

High-speed test rig for determining friction behaviour

There are many factors that influence how seals behave under friction. This high-speed test rig is used to investigate the effect of speed, temperature, medium, pressure and misalignment on seal friction behaviour.Torque 3.8 Nm Speed 30,000 rpm

10,000 rpm/sRadial displacement ± 1 mm Angular deflection 0 - 2° Media Glycol, oil Temperature control range -20° to 170 C° Internal pressure 0-6 bar Torque

3.8 Nm

Speed

30,000 rpm

10,000 rpm/s

Radial displacement

± 1 mm

Angular deflection

0 - 2°

Media

Glycol, oil

Temperature control range

-20° to 170 C°

Internal pressure

0-6 bar

Additional features:

- Concentric deflection

- Variable angle adjustment at the seal pivot

The technical data is standard data and can be altered upon request.

-

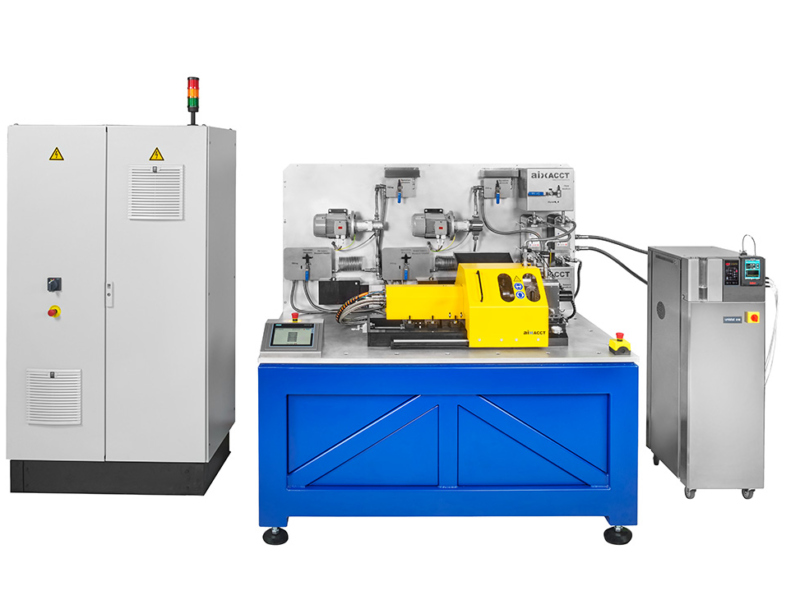

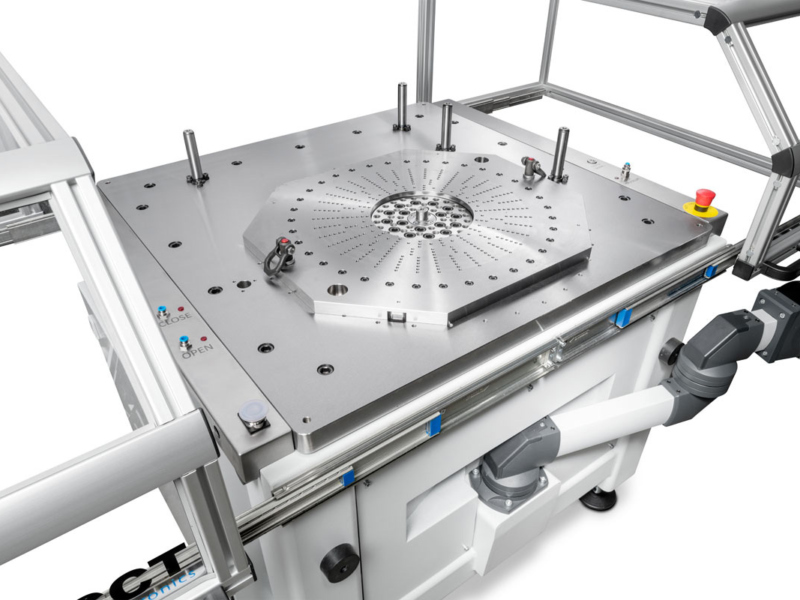

Torsion test rig for quasistatic testing of safety clamps

The Roto-Clamp combines high static torques with extremely precise angle measurement. This is essential when testing safety components, for example, and also allows users to characterise every single component.

Torque Max. 15,000 Nm Drehzahl 10 rpm Speed < 2arcsec Compressed air pressure 0 - 6 bar Test specimen identification Via 2D matrix code Test specimen programme Automatic selection Specimen-specific installation instructions OK/NOK identification Automatic test protocol Torque

Max. 15,000 Nm

Drehzahl

10 rpm

Speed

< 2arcsec

Compressed air pressure

0 - 6 bar

Test specimen identification

Via 2D matrix code

Test specimen programme

Automatic selection

Specimen-specific installation instructions

OK/NOK identification

Automatic test protocol

The technical data is standard data and can be altered upon request.